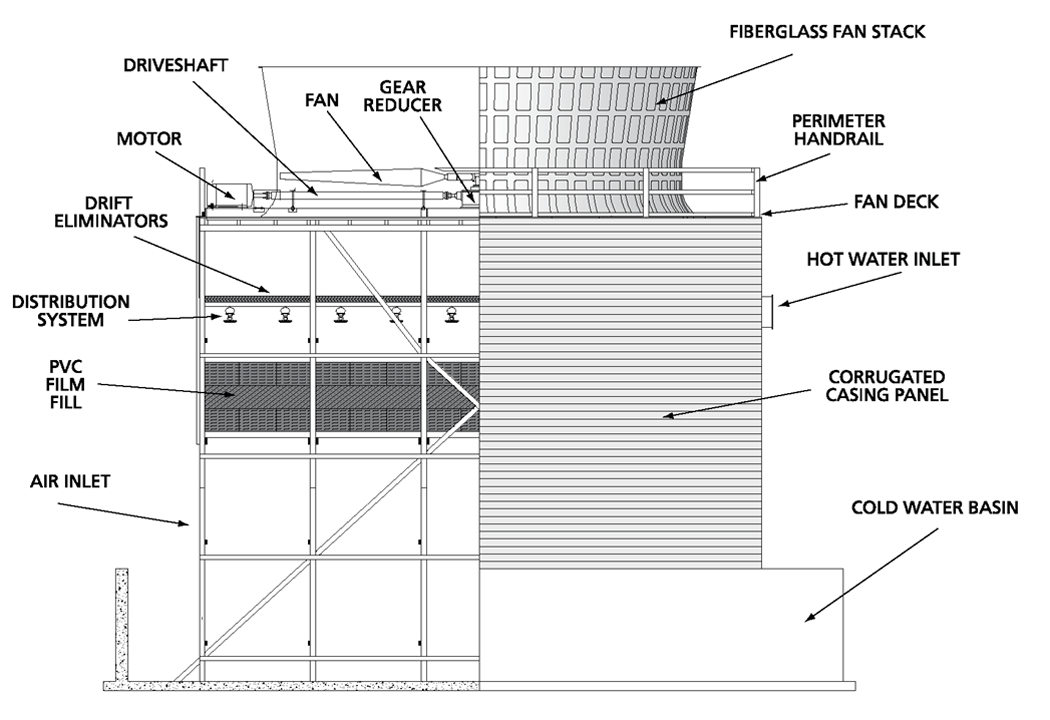

Cooling Tower LouversĪir intake louver is a part of the cooling tower that serves as a block for water splash-out, noise, and debris. The following are the cooling tower parts details including the cooling tower parts name and their functions. You could see the location of the cooling tower parts and how they are connected. the dimension are as per customer requirement, based on tower make and model no.we undertake site installation work and also supply new cooling tower as well.To give you an overview, take a glimpse of this cooling tower parts diagram below. We are also one of the leading manufacturer and supplier of sigma type fills suitable for crossflow make cooling towers. extend the service life of pvc fills for years. The edge folded technology will reduce the attrition loss of the fills and save the process equipment from fouling. Available in blue and black colors for cooling tower of FRP induced draft counter flow type and cross flow type. PERFECT offers Drift Eliminators, made out of rigid PVC, are designed to remove entrained particles from air steam efficiently, with minimum pressure drop, thereby reducing the fan power requirement when the air passes through the Drift Eliminator.Ĭooling tower fills of size 600 x 300 x 150 mm ( 1 CFT ) and 600 x 150 x 150 mm ( 1/2 CFT ) made of corrugated virging quality PVC film duly vacuum formed and edge folded for extended service life. 35 mm thick virgin PVC film vacuum formed corrugated sheets pasted together to form the size of 600 x 300 x 150 mm having wetted surface area of 5. PVC Fills for Cooling Tower - We are one of the leading manufacturer & seller of PVC honey comb type corrugated PVC fills for cooling tower. extend the service life of pvc fills for years Each fill has performance characteristics that allow selections to be made for various heat loads, flow rates, water quality, and horse power combinations.Ĭooling tower fills of size 600 x 300 ( 1 CFT ) and 600 x 150 ( 1/2 CFT ) made of corrugated virging quality PVC film duly vacuum formed and edge folded for extended service life. Film fills are selected for direct replacement, performance enhancement, and water condition compatibility. Film fills allow the water to form thin flowing sheets to expose as much water surface area as possible to the interacting flow.Ĭooling tower sheet fills or media, come in many different forms and "micro-structures," each having unique characteristics to fit various applications.

The principle of operation of cooling tower fill is to put as much water surface area in contact with as much air as possible, for the longest amount of time possible. The warmed and dampness laden air leaving the fill is released to the climate at a point remote enough from the air bays to keep its consistently stepped go into the cooling tower.

The cooled water is then gathered in a frosty water bowl beneath the fill from which it is pumped again through the procedure to assimilate more high temperature.

The water is cooled as it slides through the fill by gravity while in immediate contact with air that disregards it. The fill gives a tremendously extended air-water interface for warming of the air and vanishing to occur. Expanded surface territory considers most extreme contact between the air and the water, which takes into consideration more prominent dissipation rates. Fill, or wet deck or surface, is a medium utilized as a part of cooling towers to build the surface region of the tower. While the reason for a cooling tower rotates around water, the genuine heart of any cooling tower is the fill. Product Code: PFT-001202 Cooling Tower PVC Fills

0 kommentar(er)

0 kommentar(er)